Monitor your Grain Storage with AgroLog Manager

AgroLog Manager software, is a smart way to keep an eye on your grain storage, giving you updates on the slightest change in your facility.

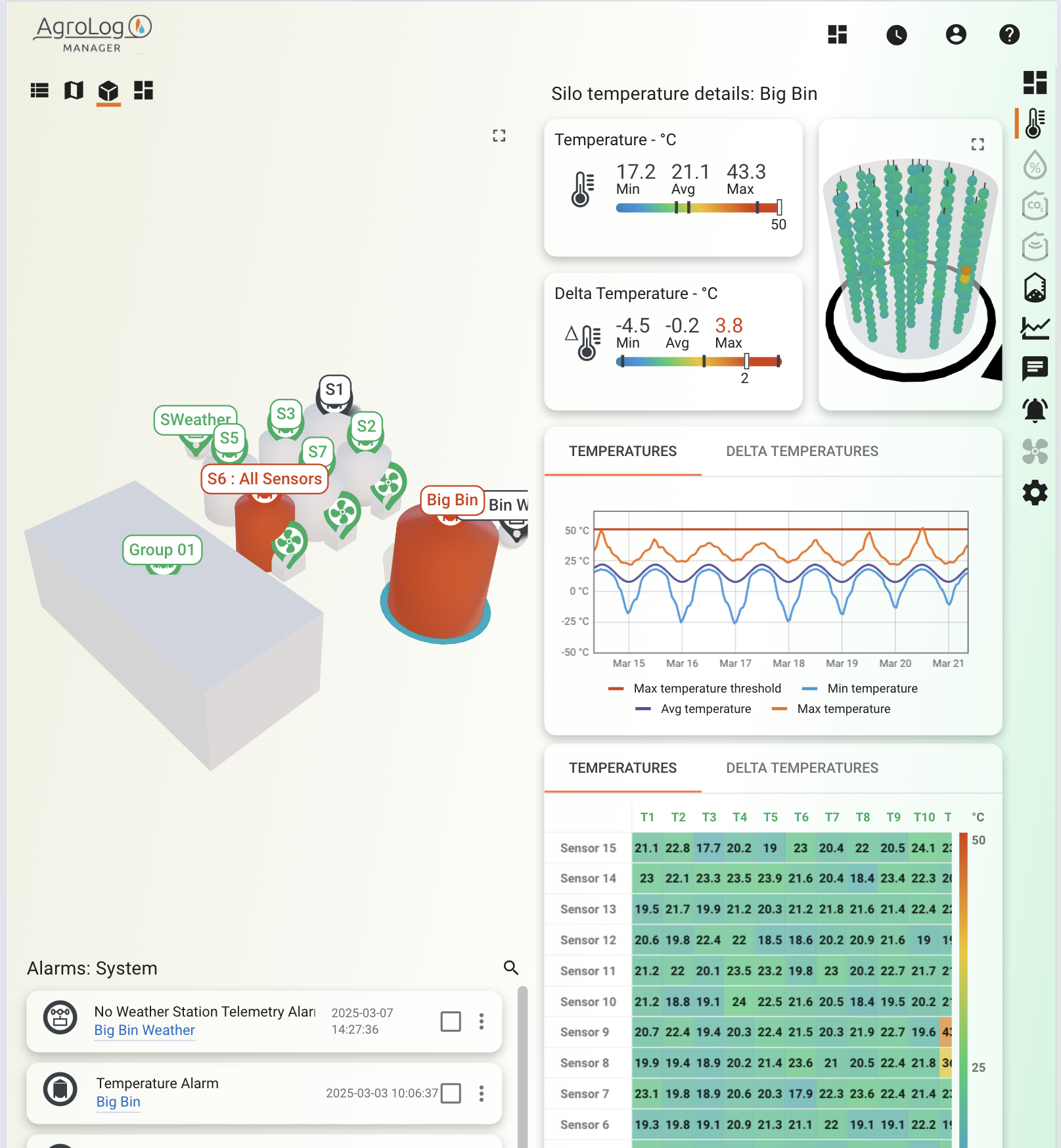

AgroLog Manager is designed to provide real-time bin monitoring and control of temperature, moisture, and CO2 levels in grain storage facilities, optimizing operations, safeguarding yield, and reducing losses. Through the software, you will be alerted about the smallest change in your storage facility, allowing you to react immediately and avoid any damage to the stored crops. Monitor multiple sites simultaneously, receive real-time and historical data, and enjoy easy and secure management from anywhere with PC, smartphone, or tablet access.

Multiple facilities in one place: Monitor all facilities in one software for efficient management and quick issue resolution.

Real-time insights: Modern interface with 3D visializations for easy data interpertation, even remotely. The intuitive interface makes it easy to spot trends, identify potential issues, and take corrective action before any damage occurs.

Get notified: Receive alerts of any change in your storage facility and react immediately.

Get value from your data: Utilize real-time data and automated reports to enhance operations, gain deeper understanding, and make informed decisions that can help to improve yields and increase profits.

Accessible from any device: Manage your storage facilities from anywhere using any device. Choose between PC, tablet, or smartphone.

Importance of Temperature Monitoring in Silos

Temperature cables are what you need to have precise and regular updates on how the temperature is evolving inside your silo or bulk storage facility.

Temperature fluctuations can indicate several potential issues, from the onset of mold and mildew to insect infestation, all of which can compromise the stored grain’s quality and safety. Effective temperature monitoring allows for early detection of these issues, enabling timely interventions to adjust conditions and prevent spoilage and losses. AgroLog's temperature sensor cable offers a sophisticated solution to this challenge. By providing precise, real-time temperature readings across different points within a silo, these sensors enable operators to maintain optimal storage conditions and react swiftly to any changes that could indicate problems.

Integrating seamlessly with the temperature sensor cables, the AgroLog Manager software collects and visualizes the temperature data in an accessible and user-friendly manner, offering tools for detailed analysis and historical data comparison. This enables storage managers to:

Detect patterns or trends that may indicate emerging issues

Implement proactive measures to mitigate risks before they escalate

Ensure that the grain remains at its highest quality throughout its storage period

With customizable alerts and the capability for remote monitoring, AgroLog Manager empowers operators to stay ahead of potential issues, safeguarding their inventory and ensuring the longevity of their stored crops.

To learn more, visit the Temperature Monitoring webpage.

The Advantage in Grain Bin’s Moisture Monitoring

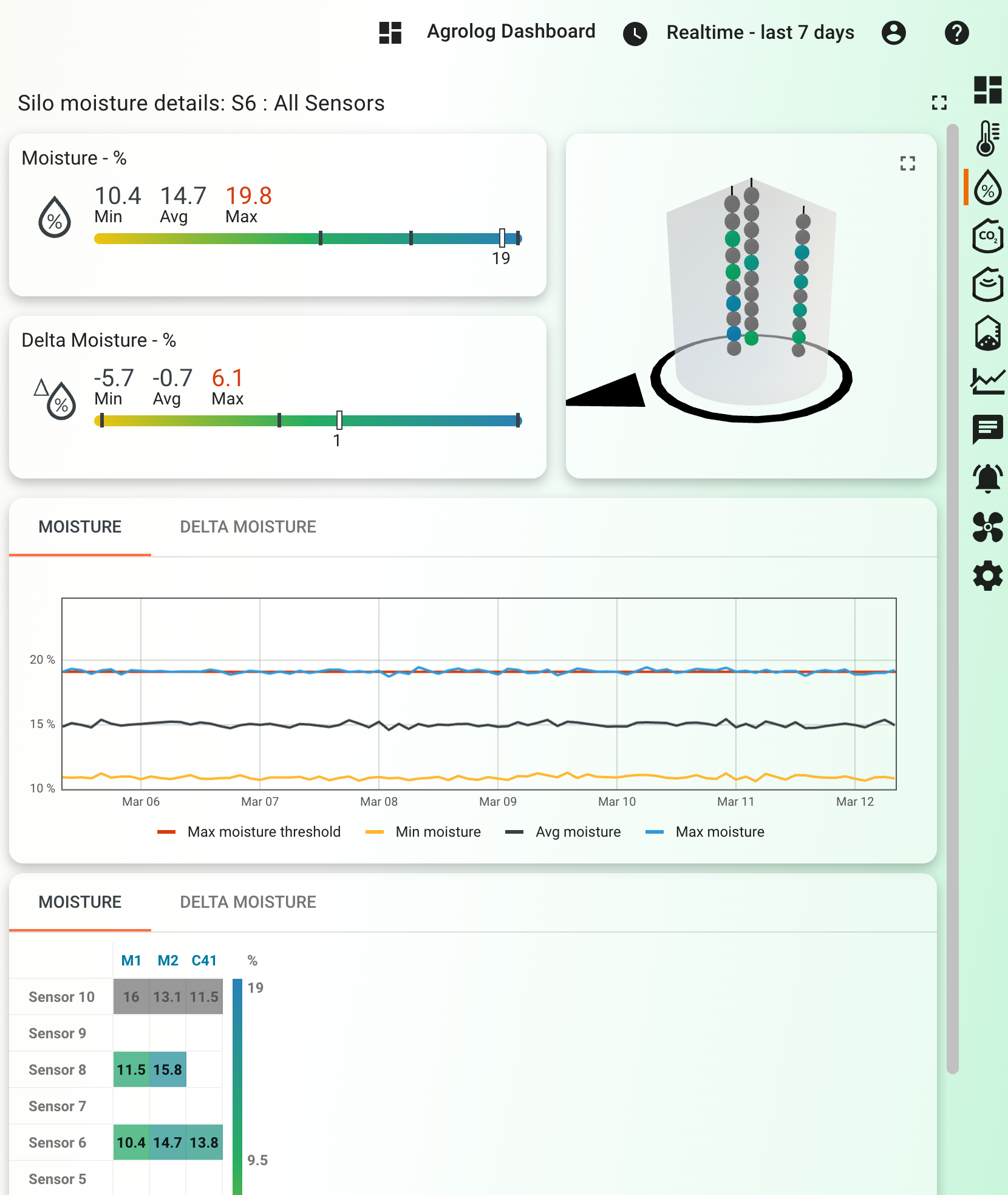

Moisture content is a critical factor in grain storage, affecting everything from the grain’s quality to its safety for consumption.

Excessive moisture can create an environment prone for the growth of mold and fungi, which can produce harmful toxins. Additionally, high moisture levels can attract pests, further jeopardizing the grain’s quality and leading to significant losses. Conversely, too little moisture can lead to over-drying, which compromises the grain’s nutritional value and market worth. Thus, accurate moisture monitoring is indispensable for maintaining the delicate balance required for optimal grain storage.

Integration with temperature cables and monitoring with the AgroLog Manager software offers a proactive approach to grain management.

Precise, Real-Time Moisture Data: Ensures optimal grain storage conditions.

Comprehensive Silo Coverage: Detailed moisture insights at various points within the silo.

Proactive Problem Mitigation: Enables swift action to maintain grain quality.

Data-Driven Decision Making: Trends analysis and customizable alerts for moisture levels.

Maximized Grain Quality and Profitability: Protects against spoilage, mold, and pests.

Future-Proof Storage Management: Adopts a more efficient, data-driven approach to farming and storage management.

AgroLog's moisture monitoring solutions offer more than just data; they provide the insights necessary for making informed decisions that protect and enhance the value of stored grains.

Read more about moisture monitoring here.

Headspace Insights for Effective Grain Monitoring

Managing the headspace environment within silos and grain bins is crucial for maintaining the quality of your stored grain.

Sudden temperature shifts , especially from day to night, can lead to condensation, posing a significant risk of “rain” inside the silo which can damage the stored crops. AgroLog's headspace sensor is strategically placed to detect these conditions early, allowing for proactive measures to mitigate potential damage.

Beyond temperature and moisture, the level of CO2 in the headspace is a vital indicator of the grain’s health. Elevated CO2 levels can signify the presence of microorganisms that spoil the stored grain by consuming its sugars. AgroLog's sensor technology captures these changes in CO2 levels, offering an early warning that allows for timely intervention.

Multi-Measurement: Real-time, high-quality readings of CO2, Temperature, EMC, Dewpoint, and Relative Humidity in the headspace.

CO2 Monitoring: Detects levels from 0 to 10000 ppm, serving as an early warning system for the presence of harmful microorganisms that may spoil your crops.

Condensation Prevention: Recognizes swift temperature drops that may lead to harmful condensation, sending alerts to prevent "rain" inside the silo.

Full Integration: Seamlessly works with AgroLog software, allowing you to react promptly to any changes.

Customizable Alerts: Set thresholds to receive alerts when CO2 levels fall outside of a safe range, enabling you to quickly address any issues that arise.

AgroLog's headspace sensor, coupled with the AgroLog Monitor software, represents a significant advancement in storage technology. This combination not only enhances the ability to monitor and manage the conditions within silos and grain bins but also empowers operators with the data and tools necessary for making informed decisions. By integrating this sensor into your storage management practices, you can protect your crops from spoilage, maximize yield, and maintain the highest quality of stored grains.

Read more of the AgroLog Headspace Sensor here.

The Role of Crop Level Monitoring in Grain Management

Automation in grain management introduces unmatched efficiency and the manual labor traditionally required is significantly reduced. Automation means that real-time data is always available, enabling quick decision-making that can dramatically reduce waste, improve safety, and optimize operational workflow.

AgroLog’s level monitoring technology, integrated with AgroLog Manager software highlights its benefits. The platform provides a user-friendly interface for managing the data gathered by the monitoring systems. It allows for detailed analysis, customizable alerts based on specific thresholds, and even predictive insights for future storage needs. Essentially, AgroLog Manager turns data into actionable intelligence, enabling operators to maintain optimal storage conditions and make informed decisions that boost efficiency and profitability.

Real-time, accurate crop level monitoring for optimal inventory management

Automated data collection reduces manual labor and increases efficiency

Enhanced operational safety by preventing overfilling and managing storage conditions

Improved quality control of stored crops through precise environmental monitoring

Detailed data analysis and customizable alerts

Facilitates sustainable agriculture practices by minimizing waste and optimizing resource use

Beyond the immediate operational benefits, the adoption of advanced monitoring technologies reflects a broader move towards sustainability in agriculture. By optimizing storage conditions and reducing waste, the technologies support the efficient use of resources - a crucial aspect in global food scarcity and the push for environmental sustainability.

Read more of our Crop Level Monitoring Bob and Crop Level Monitoring Radar to learn more.