How do you fill a Grain Silo?

Filling a grain silo efficiently and safely is essential to preserve your harvest’s quality and maximize storage capacity. With modern technology, like AgroLog’s advanced inventory monitoring systems, managing this process has become more precise, safer, and easier than ever before.

Step 1: Preparation and Setup

Before filling your silo, make sure it is clean, dry, and structurally sound. Inspect for any damage or debris, and repair or clean as needed. Prepare your filling equipment such as conveyors or augers, and make sure everything is in good working order to avoid delays or accidents during filling.

Step 2: Use Radar Technology and Inventory Monitoring Solutions

Accurate and continuous monitoring of grain levels during silo filling is essential for efficiency and safety. AgroLog offers a suite of advanced inventory monitoring products designed to provide real-time insights into your grain storage:

CLM Radar

A precision radar sensor providing real-time, continuous grain level monitoring—designed to enhance safety, prevent overfilling, and support accurate inventory control for efficient grain management.

Crop Level Measurement Radar

This radar sensor accurately measures the grain level inside the silo without physical contact. It operates reliably under harsh conditions such as dust, temperature changes, and vibrations, providing real-time data that helps prevent overfilling and ensures optimal silo utilization.Crop Level Measurement Bob

For applications where radar isn’t suitable, AgroLog’s automatic mechanical level sensors offer precise level tracking by detecting the physical position of the grain surface. ATEX approved, these sensors are easy to install and integrate seamlessly with the AgroLog monitoring platform.Inventory from Temperature

Thanks to our advanced grain inventory monitoring, AgroLog Manager accurately determines grain levels in silos using data from our temperature sensor cables. The software analyzes sensor readings to distinguish between grain and empty space, enabling effective inventory management without the need for additional level sensors.

s

s

Step 3: Monitor and Adjust Filling Process

As grain flows into the silo, continuously monitor the level data provided by AgroLog’s sensors. Adjust the filling rate as needed to ensure even grain distribution and avoid overfilling. The real-time alerts keep you informed, enabling quick action to prevent spills or structural stress on the silo.

Step 4: Post-Filling Inspection and Maintenance

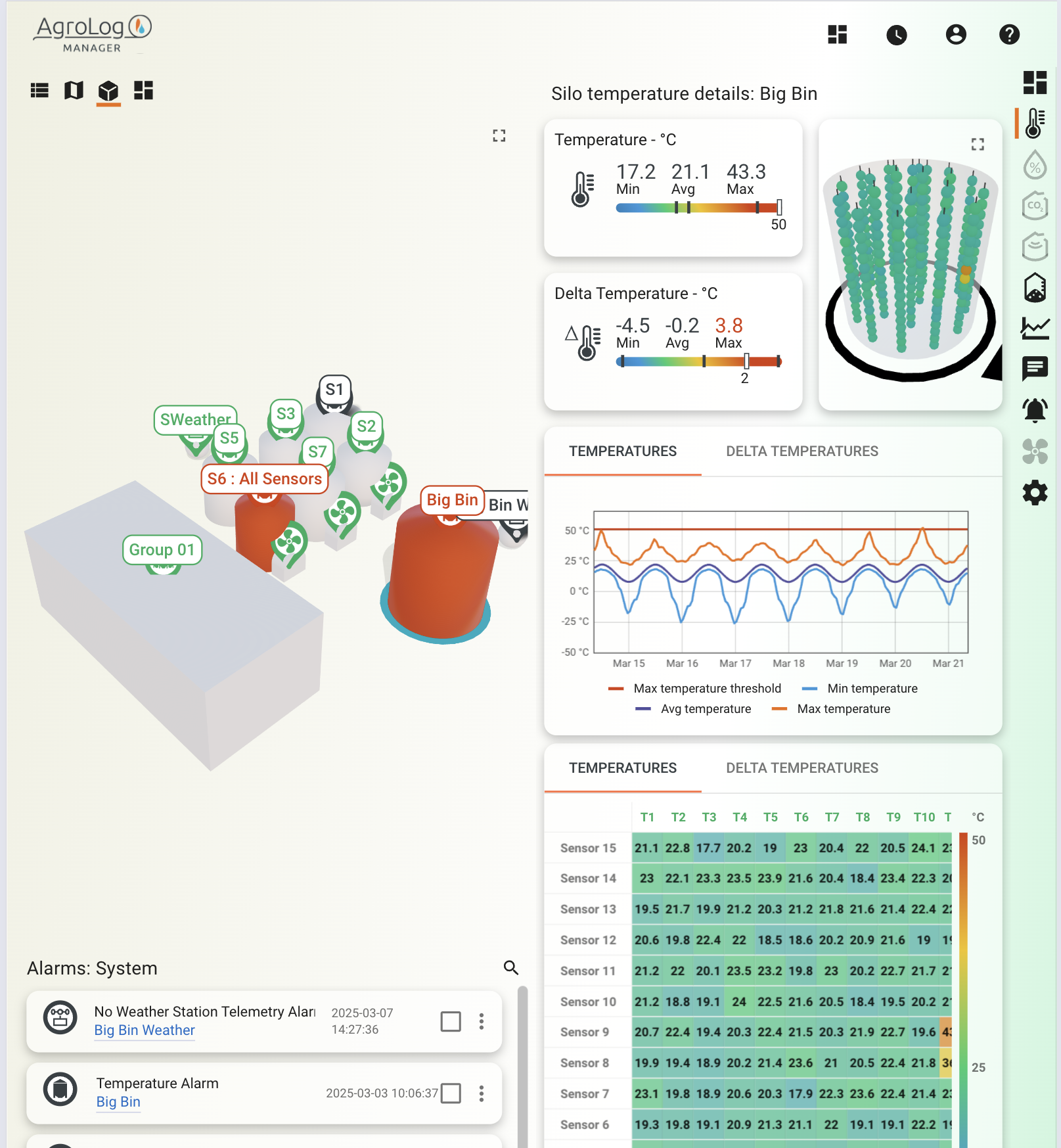

AgroLog Manager

Intuitive software platform providing real-time access to crop level sensor data and key insights, enabling smarter decision-making and streamlined grain management operations.

Once your silo is filled, perform a thorough inspection to verify even grain distribution and check the integrity of the silo structure.

Regular monitoring with AgroLog’s Manager software helps you detect potential issues like moisture buildup or hotspots early, protecting your grain’s quality throughout storage.

s

s

s

s

s

If you want to improve the way you manage grain silos and ensure safe, efficient storage, AgroLog offers the tools you need. Contact us today to learn more.